The X440 is the first motorcycle to result from the great collaboration between Hero MotoCorp and Harley-Davidson. While that alone makes it a product significant enough for Hero to demonstrate its production process, another factor is the infrastructure and architecture of the location where it is produced. The X440 is manufactured, or rather assembled, at Hero’s Neemrana Garden facility. Aside from manufacturing motorcycles, the company engages in innovative farming practices within the facility with the goal of significantly reducing their carbon impact. Hero MotoCorp brought us to their 47-acre Neemrana Garden factory so that we could see and experience everything for ourselves.

Aside from taking us up close to the fresh cherry tomatoes grown on the factory’s roof through hydroponic farming, a representative walked us through the entire process of how 250 units of the X440 are built in the facility every day, beginning with the engine assembly line, frame assembly line and paint shop and ending with the inspection and storage areas.

Once the internal components of the engine are acquired from vendors, they are assembled using a process that incorporates 70% automation and robotics and only 30% human participation. All of the components are assembled after passing through 37 different steps, or dollies, as factory officials call them, on the engine assembly line. These sections contain tappet adjustment, flywheel fitment, cam chain fitment, timing adjustment, and many others.

With 30% human involvement, there is a chance of unintended errors. To avoid this, Hero has embraced a Japanese notion known as ‘Poka Yoke’. This system’s fundamental premise is to execute an automatic check for faults during component installation. This is done after each of the 37 steps have been completed and before the assembly moves on to the next level. The inspection is primarily performed to confirm that all relevant parts have been removed from the bin and that nothing has been overlooked. This notion also applies to the frame assembly line.

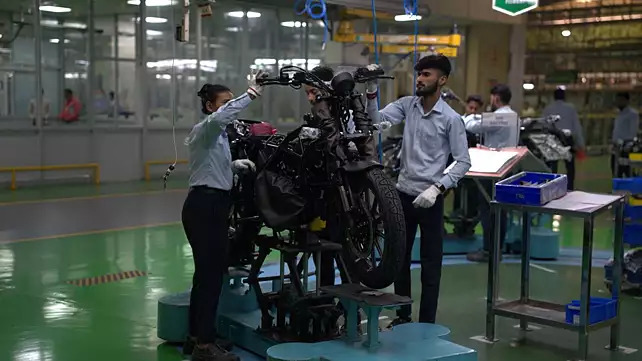

Once the engine is completed, it is sent to the frame assembly line, where the engine and cycle sections are assembled in 27 steps, with a Poka Yoke module between each two steps. The assembly process begins with just the engine and the primary frame, followed by the installation of other components such as suspension, brakes, wheels, etc. A battery-operated torque wrench manages and guarantees that components are properly tightened together. Interestingly, the engine parts on this model are completely covered to prevent scratches and finish loss.

Hero features a separate component for building the gasoline tank. It is made up of two welded sections that have been thoroughly inspected. Before delivering it to the assembly line, the experts inspect it thoroughly for wear and dry leaks using air pumps, as well as the adhesiveness of the seam link between the top and bottom parts.

Regardless of whether Poka Yoke or the mistake-proofing system is used, each unit of the X440 passes through 225 manual and automated checkpoints, leaving no opportunity for error. At the intermediate step, every major and minor component is automatically tested for fitting and damage. This is followed by the final testing phase, in which the motorcycle is removed from the assembly to undergo a rigorous manual inspection process. The final testing is carried out in five stages. In the first two stages, factory personnel inspect the bike’s safety features, such as the proper operation of the brakes. The third level includes a performance test with a dynamometer, while the fourth level ensures proper speedometer operation. The fifth stage is all about inspecting the appearance and feel using a rigorous visual scan and touch.

When the motorcycles are ready to depart the factory floor, they are placed on a massive metal structure known as the Automated Storage and Retrieval System. Simply said, it’s a gigantic multi-story rack with chambers for loading and retrieving motorcycles as needed. ASSR, like the majority of the plant’s other sections, is an automated system, with automatic loading and retrieval.

Furthermore, the system is intended to allow users to locate and retrieve specific units without affecting the position of other units, if necessary. ASSR can store up to 1,500 X440 units at a time. In case you’re wondering, every unit of the X440 takes two hours to travel from the initial stage of manufacture to the storage area.